The Pharmaceutical Factory of the Future Is Here – and It Uses Meddle

Published on: June 15, 2025

Author: Michele Lacorte, CTO

Use Case – Pharmaceutical and Biotechnology

A leading pharmaceutical company needed to strengthen batch traceability, ensure regulatory compliance, and improve integration between production lines and ERP/GMP systems.

The Challenge: Compliance and Full Control

In highly regulated environments like the pharmaceutical sector, collecting accurate and traceable data is essential. However, the company had to manage manual processes, isolated systems, and difficult data validation for inspection and audit purposes.

Challenges Identified:

- Lack of continuous traceability along the line

- Poor integration between field and ERP systems

- Risk of non-compliance in FDA and GMP audits

The Solution: Meddle for Regulated Industries

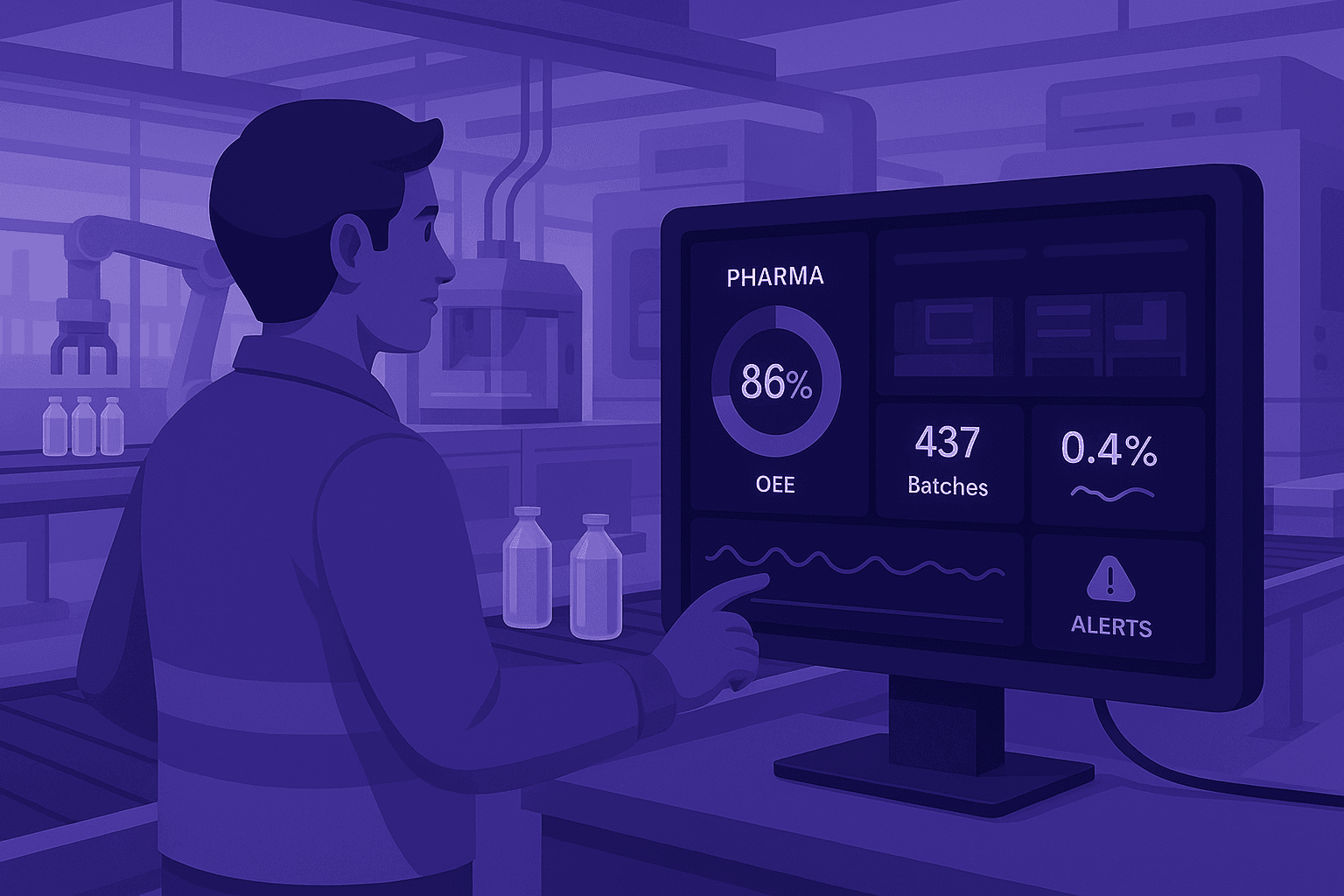

By implementing Meddle, the company would gain access to a centralized and configurable supervision system capable of automatically collecting process data from machines and sensors, ensuring compliance with pharmaceutical and biotech regulations.

Key Features:

- End-to-end traceability of production batches

- Data validation compliant with FDA/GMP regulations

- Seamless integration with ERP and quality systems

- Secure and auditable storage of collected data

Results for the Pharmaceutical Company

Meddle delivers immediate and measurable benefits:

- Easier preparation for audits and inspections

- Automated process documentation

- Reduced risk of non-compliance

- Better integration between field and central systems

Why Pharma Companies Choose Meddle

Meddle is designed to support regulated companies in digitalizing their processes, ensuring data integrity, security, and compliance with major international standards such as FDA 21 CFR Part 11, GAMP5, and GMP.