Meddle for Printing and Paper Converting: Quality and Efficiency in Focus

Published on: June 15, 2025

Author: Michele Lacorte, CTO

The Challenge: Process Monitoring and Consistent Quality

In industrial printing and converting, even small deviations can ruin entire print runs or delay shipments. Companies manage complex production lines—printing, cutting, folding, gluing—with machines from various vendors, often without integration. Quality control is often sample-based, and live production data is fragmented, making problem detection difficult.

The Solution: Meddle for Digital Production Control

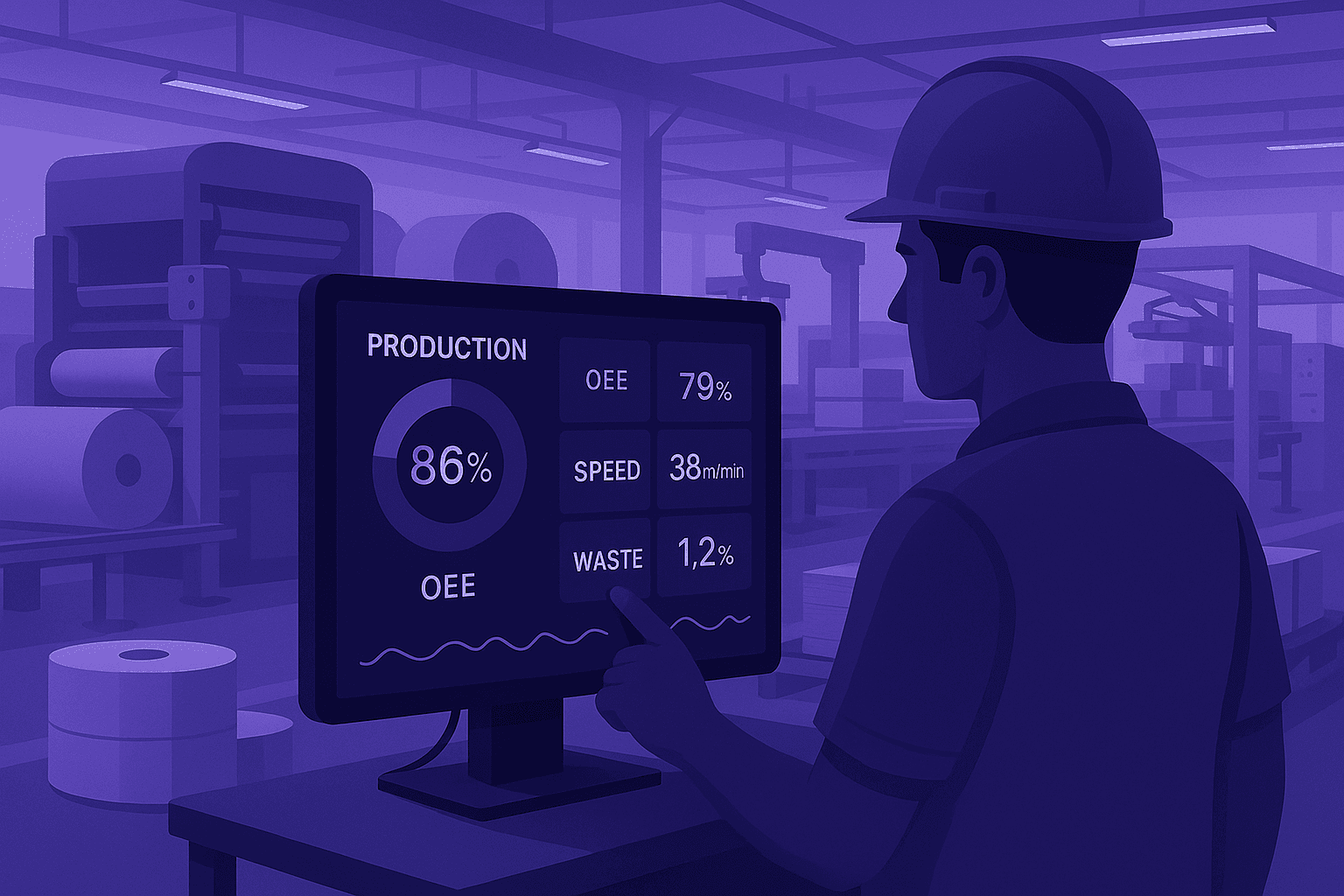

Meddle digitizes the full workflow, from raw rolls to final packaging. It connects to PLCs, sensors, and machine systems to monitor real-time data like speed, temperature, humidity, alarms, energy usage, and waste. Custom dashboards visualize key KPIs like OEE, downtimes, quality, and production flow. Meddle’s no-code approach works with new and legacy systems alike.

Benefits for Printing and Converting Plants

Meddle enables up to 60% fewer machine stoppages, continuous quality control, and smarter batch management. All data is audit-ready, supports traceability, and drives operational optimization. With Meddle, the printing and packaging industry steps into a new era of smart manufacturing.