Meddle for Electronics and Semiconductors: Precision and Full Process Control

Published on: June 15, 2025

Author: Michele Lacorte, CTO

The Challenge: High-Precision Production in Critical Environments

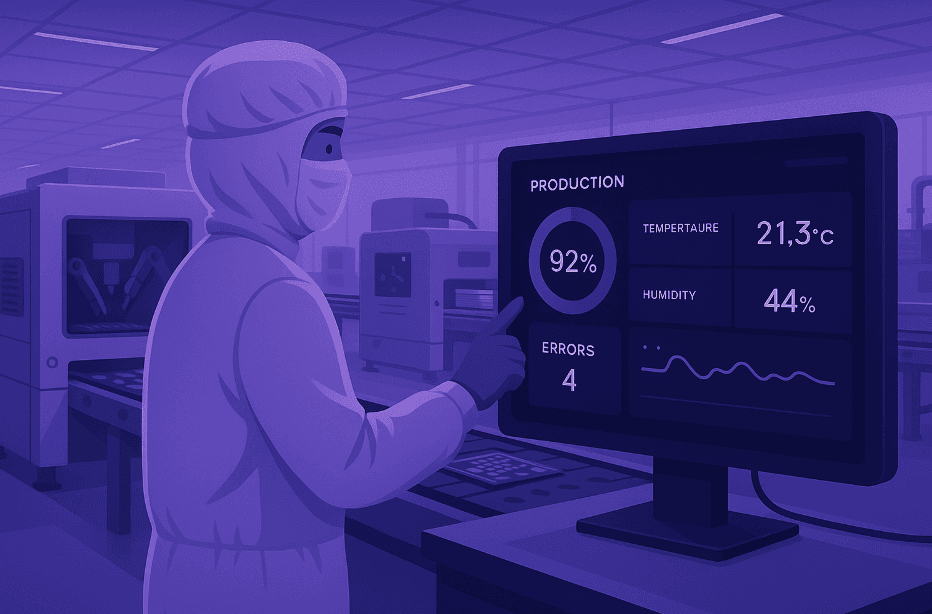

Electronics and semiconductor manufacturing demand tight control over environmental and process parameters—temperature, humidity, vibrations, and particle contamination can all affect product quality. Facilities rely on specialized machines and automation, often operating in silos. Real-time monitoring of each process variable is key to minimizing waste and ensuring compliance with standards like IPC-A-610 or ISO TS 16949.

The Solution: Meddle for Integrated and Scalable Supervision

Meddle connects to all machines, sensors, and control systems across the production line, providing real-time, code-free dashboards. It monitors soldering stations, pick-and-place robots, reflow ovens, and cleanroom parameters. Supporting industry-standard protocols, Meddle is ideal for high-tech environments requiring full process traceability and fast diagnostics.

Benefits for the Electronics and Semiconductor Sector

By using Meddle, companies reduce unplanned downtime, increase yield, and automate compliance reporting. Continuous supervision enables predictive maintenance, trend analysis, and fast audit preparation. Meddle becomes the digital backbone of electronic manufacturing, ensuring quality, consistency, and productivity.