How the Food Industry Can Embrace Safe Digitalization with Meddle

Published on: June 15, 2025

Author: Michele Lacorte, CTO

Food Industry Challenges: Traceability and Strict Regulations

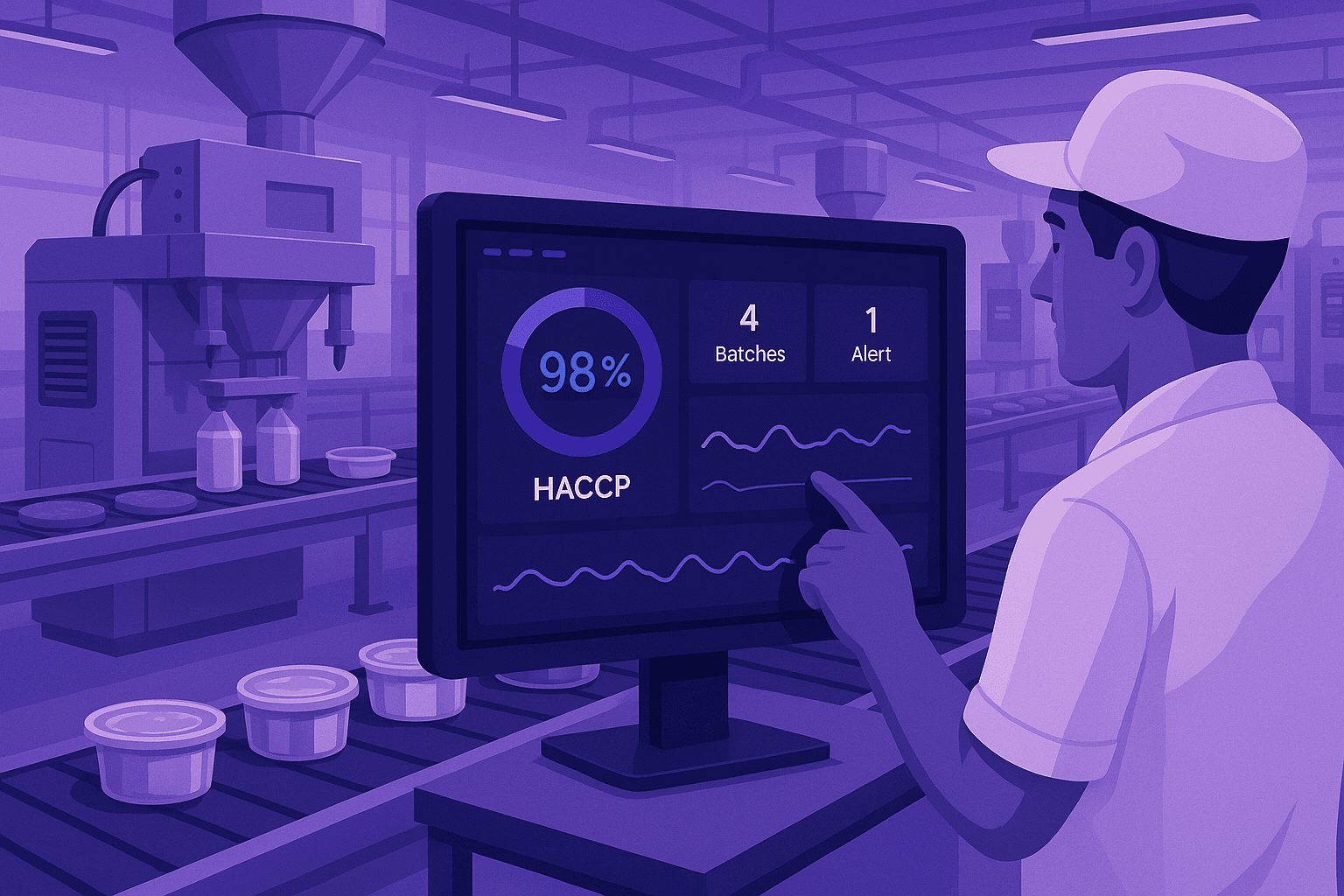

In the food sector, ensuring product quality and safety is not just a goal—it's a regulatory necessity. Companies face complex operations that require strict quality control, regulatory compliance, lot traceability, and rapid response to any issues. Many plants still rely on a mix of old machinery and disconnected systems, resulting in fragmented data and slower decisions, which can jeopardize compliance with standards like HACCP, ISO 22000, or BRC.

The Solution: Meddle as IIoT Supervisor for Food Production

Meddle turns any food production facility into a smart factory. By connecting directly to existing PLCs and sensors, it centralizes and normalizes critical data in real time—temperature, pressure, cycle times, humidity, alarms, and downtimes. This empowers companies to respond quickly, reduce waste, and ensure full traceability across the production chain. With a no-code interface and compatibility with industry-standard protocols, Meddle is deployable even in environments with limited IT resources.

Results and Benefits for the Food Sector

Meddle brings measurable improvements to the food industry: 75% reduction in response time to non-compliance events, 60% fewer downtimes due to real-time alerts, and full compliance with traceability regulations. Data is securely archived and accessible remotely for audits and inspections. Meddle is a strategic partner for companies in the food sector seeking a safer, smarter, and more efficient production environment.