How Meddle Enhances Safety and Efficiency in the Chemical and Petrochemical Industry

Published on: June 15, 2025

Author: Michele Lacorte, CTO

Chemical Sector Challenges: Critical Data and Sensitive Processes

In the chemical and petrochemical sectors, even the smallest deviation can lead to major safety risks, quality issues, or costly downtimes. These industries rely on precise, continuous control over complex reactions and hazardous substances. Ensuring compliance with standards such as REACH or ATEX and collecting accurate real-time data are crucial—but many plants still operate with outdated or siloed systems.

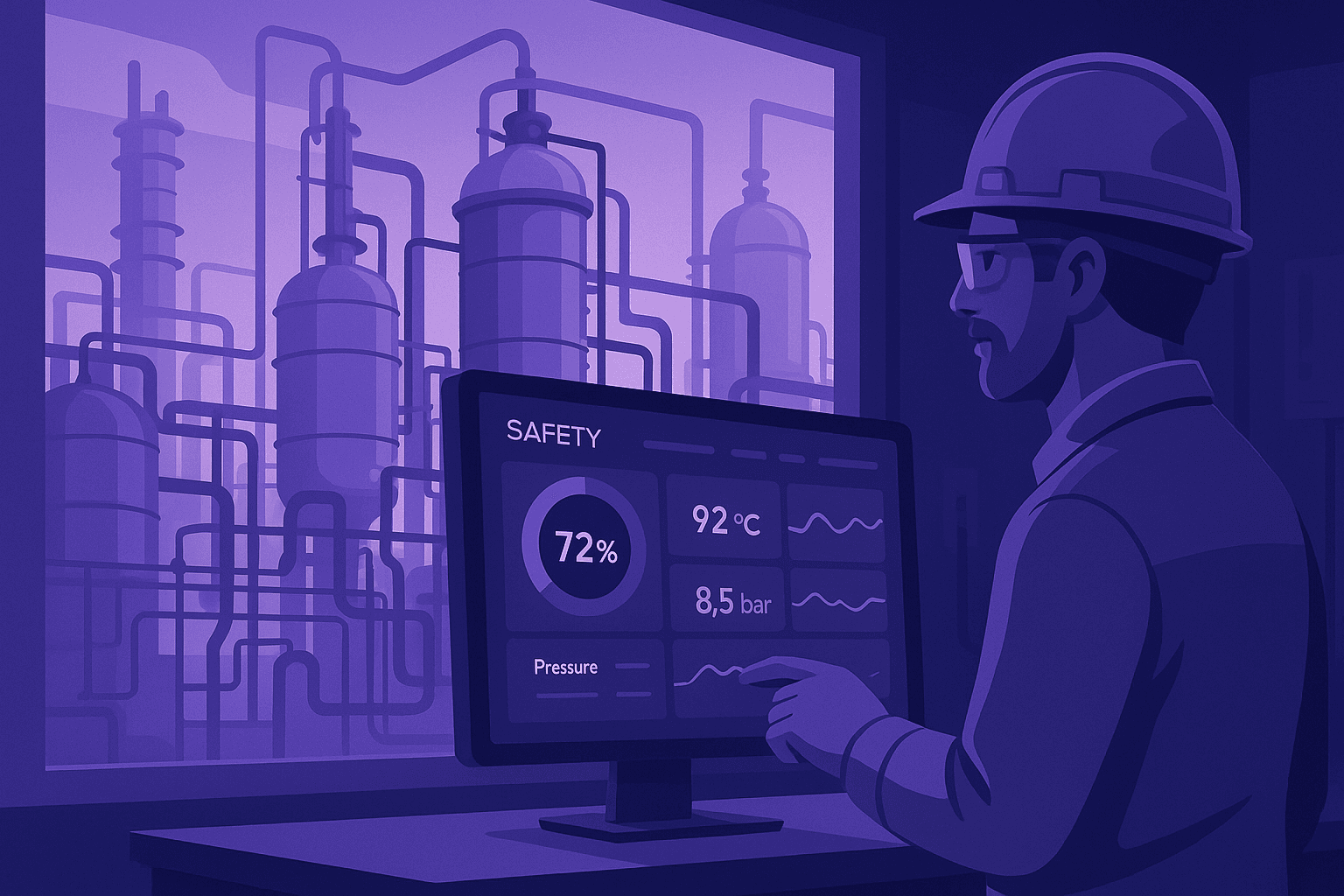

The Solution: Real-Time IIoT Supervision with Meddle

Meddle provides a centralized, scalable solution that connects directly with existing PLCs, sensors, and instruments to capture real-time data such as temperature, pressure, flow rates, and valve status. These are displayed through interactive dashboards and alerts without any coding required. Thanks to its no-code approach and distributed architecture, Meddle fits both compact setups and complex, multi-site infrastructures.

Results and Benefits for the Chemical Sector

Companies implementing Meddle have achieved continuous predictive monitoring, a 70% reduction in unexpected downtimes, and full regulatory compliance. With clearer process visibility, automated reporting, and safer operations, the chemical and petrochemical industries can transition toward smarter, more resilient production environments.