Industrial IoT for Automotive: Smart Manufacturing with Meddle

Published on: June 15, 2025

Author: Michele Lacorte, CTO

Introduction

A major automotive manufacturing company has started construction of a new smart factory dedicated to the production of electric vehicles (EVs). This next-generation plant was designed according to the most advanced principles of smart manufacturing and Industry 4.0, with a heterogeneous production line in terms of machinery, sensors and data visualization tools.

The Challenge: Data Interoperability

The company faced a critical issue common to many industries: the difficulty of collecting and unifying data from different machines, each with its own communication protocols. The result was a fragmented ecosystem that was difficult to monitor and optimize in real time.

Problems encountered

- Fragmented data across different protocols and vendors

- High cost and long time for manual integrations

- Lack of flexibility in adapting data collection to production changes

The Solution: Meddle as Line Supervisor

By implementing Meddle, the company would have a single, flexible and scalable line supervisor that could integrate with any industrial protocol and collect data from across the production line.

Key features

- Universal connection with any machinery or sensor

- Automatic normalization of data into a single format

- Autonomous configuration of collection rules and sampling rates

- No additional hardware required

- Deploy as an on-premise version for full data control

Results for the Automotive Company

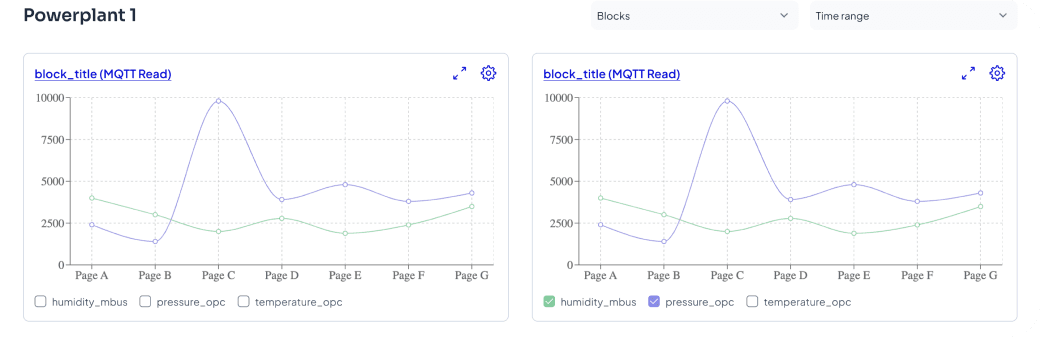

Meddle produces immediate and measurable benefits:

- 90% reduction in setup time for data collection

- Real-time monitoring across the entire production line

- Total autonomy in information flow management

- Compliance with Industry 4.0 standards

Conclusion

Meddle is the ideal solution for those in the automotive industry who want to make their factories smart. With its no-code architecture, multi-protocol compatibility, and ease of use, it reduces the cost, time, and complexity of industrial integration.