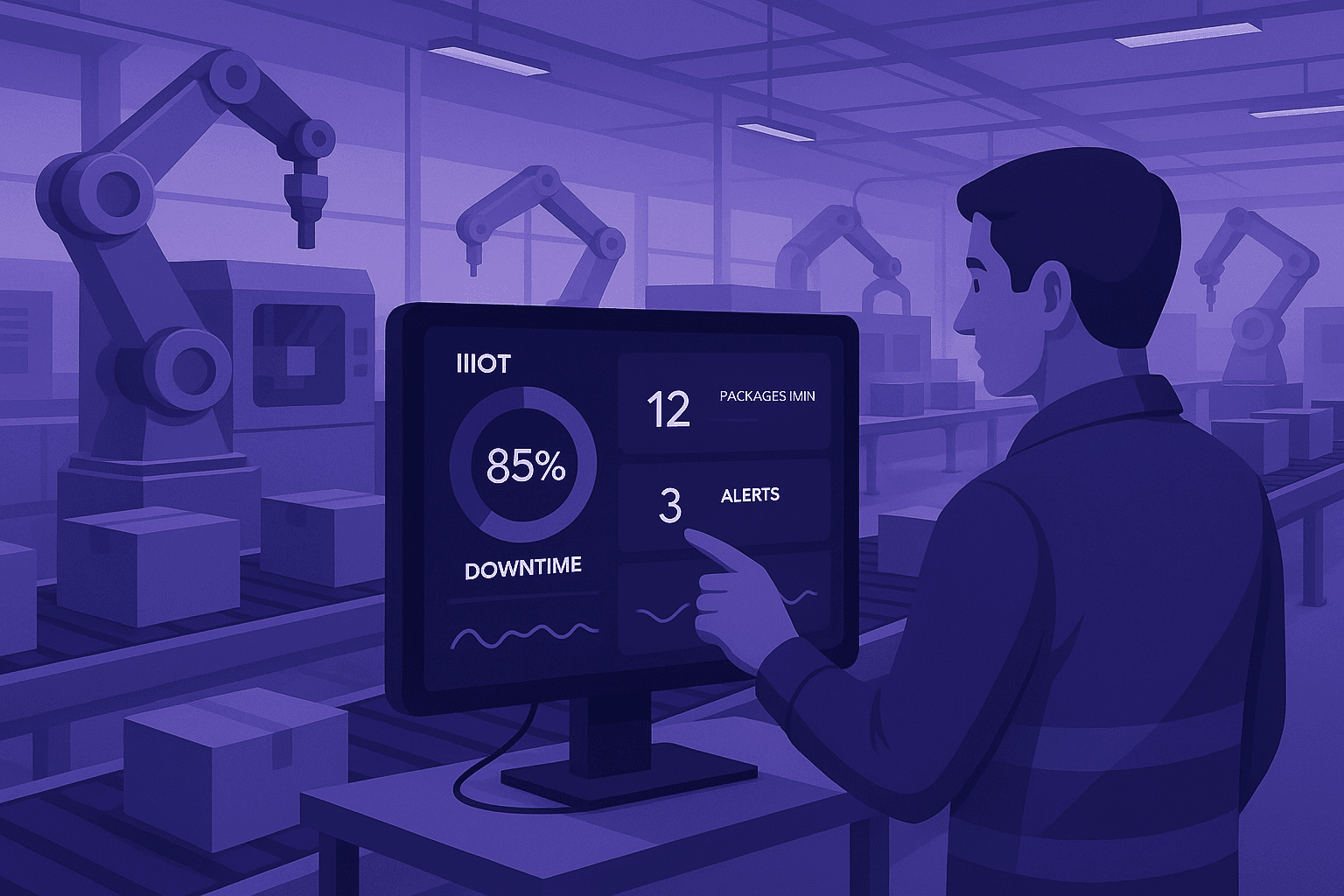

-85% Line Stops: The IIoT Revolution in a Packaging Industry

Published on: June 15, 2025

Author: Michele Lacorte, CTO

Use Case – Packaging / Container Sector

A leading company in the packaging sector, specialized in bottling and canning, aimed to improve the efficiency of its production lines and reduce waste, while maintaining high quality standards in packaging.

The Challenge: Real-time Monitoring and Control

The company faced a line infrastructure composed of heterogeneous machines and sensors, with poor integration between quality control systems and production devices. Data collection was fragmented and often required manual operations or external interventions.

Challenges encountered:

- Difficulty in detecting anomalies or defects in a timely manner

- Poor traceability of batches and processes

- High operating costs due to lack of advanced automation

The Solution: Meddle as Line Supervisor

By implementing Meddle, the company would have had a single, flexible, and scalable line supervisor capable of integrating with existing PLCs and sensors to collect, normalize, and analyze process data in real-time.

Key Features:

- Direct connection to PLCs for immediate reading of machine signals

- Automatic waste reduction thanks to continuous monitoring

- Support for quality inspections with consolidated and filterable data

- No-code configuration to modify variables and sampling frequencies

Results for the Packaging Company

Meddle delivers immediate and measurable benefits:

- -85% in line stops thanks to real-time notifications

- Higher quality of the finished product

- Better traceability of production processes

- Fewer external interventions required to reconfigure systems

Why Packaging Companies Choose Meddle

Packaging companies choose Meddle for its ability to directly connect to machines, optimize line performance, and provide a comprehensive view of production without the need for custom software development.